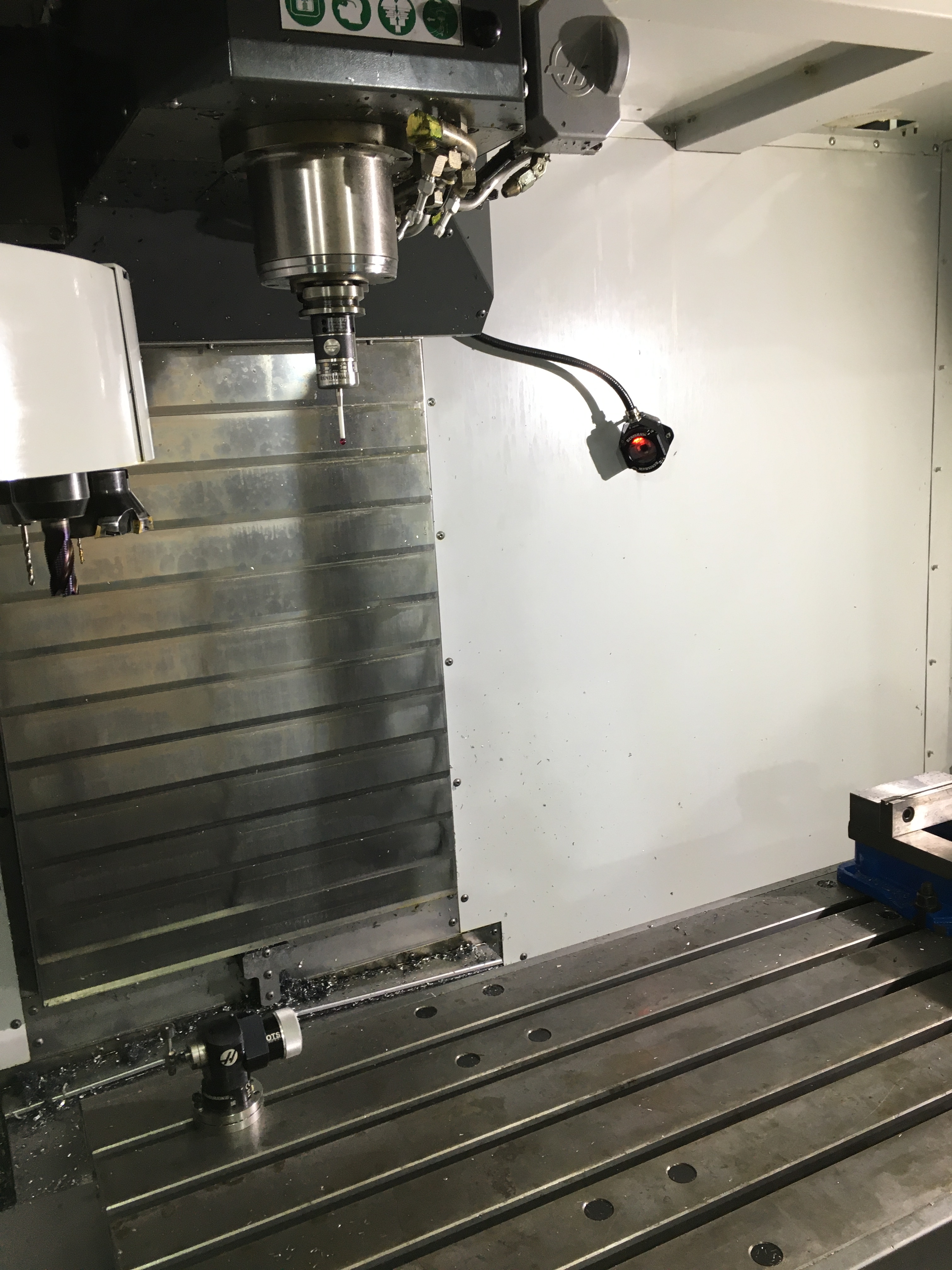

We have recently invested in a new Haas VF4 Vertical Machining Center equipped with Haas Wireless Intuitive Probing System. WIPS has the ability to define work offset coordinates, set tool length offsets, and perform in-process inspection within the program in so doing reducing set up times and increasing quality.

Along with the VMC we have invested in a Tesa MH3D454 Coordinate Measuring Machine equipped with the latest PC-DMIS metrology software enabling us to inspect our parts and produce clear inspection reports for our customers if required.

Mazak Model Nexus 410A-II Vertical Machining Centre (travel X 560 mm, Y 410 mm, Z 500 mm)

Mazak Model SQT 250 CNC Lathe, T PLUS Control

Haas VF Vertical Machining Centre (travel X 760 mm, Y 550 mm, Z 500 mm)

Haas VF4 Vertical Machining Centre (travel X 1016 mm, Y 506 mm, Z 635 mm)

Flat bed CNC router capacity 2550mm x 1255mm x 400mm, spindle speed 2500 rpm, 12 ATC and vacuum bed

Manual milling and turning.

Tesa MH3D454 CMM with the latest Pc-Dmis software

We run 2 machine shops, one wet in which we machine metallic and material requiring coolants and the second is dry, an area which is free of oils and coolants for, here we machine CFRP along with other material which are required dry machining.